Food Grade Centrifugal Separator

Productivity, Reliability, Freshness

Tables, kitchens and pantries of all sizes are stocked full of processed foods and beverages that require the power, precision and performance of B&P Littleford’s high-quality, low-maintenance mixing and separation equipment.

For more than a century, B&P Littleford has designed, developed and delivered durable, reliable mixers and separators that help process thousands of food and beverage products and ingredients. Get a quote now.

Food Grade Centrifugal Separators

B&P Littleford’s mixers and separators are expertly engineered, skillfully crafted and rigidly tested to meet your exacting sanitary, food grade specifications, and handle the most challenging food processing applications no matter what their form - wet or dry, cold or hot, coarse or fine, sanitary or aseptic.

Foodstuff Applications

Use B&P Littleford’s quality mixing and separating equipment to process:

- Proteins

- Grated Cheese

- Cocoa

- Bread Mix

- Cake Mix

- Spices

- Drink Mix

- Soft Drink Powder,

- Gelatin Dessert

- Soybean Meal

- Animal Feed

- Tea

- Sugar

- Frosting

- Coffee Beans

- Oats,

- Candy

- Citric Acid

- Soup Mix,

- Flax Seed

- Pectin

- Vanilla Bean

- Bouillon

- Dextrins

| Application | Equipment |

| Liquid smoke | POD |

| Citric Acid | POD |

| Citral extraction from Limonine | POD |

| Hops extraction | POD |

| Cooking oil | POD |

| Oleic Oils | POD |

| Lauric Oils | POD |

| Calcium Tartrate | Pusher |

| Food Products | Double Arm |

| Proteins | Plow Mixer |

| Grated Cheese | Plow Mixer |

| Cocoa | Plow Mixer |

| Starch Reaction | Plow Mixer |

| Bread Mix | Plow Mixer |

| Cake Mix | Plow Mixer |

| Spices | Plow Mixer |

| Drink Mix | Plow Mixer |

| Soft Drink Powder | Plow Mixer |

| Gelatin Dessert | Plow Mixer |

| Grain | Plow Mixer |

| Wheat | Plow Mixer |

| Soybean Meal | Plow Mixer |

| Animal Feed | Plow Mixer |

| Tea Powders | Plow Mixer |

| Sugar | Plow Mixer |

| Frosting | Plow Mixer |

| Coffee Beans | Plow Mixer |

| Oats | Plow Mixer |

| Dextrin | Plow Mixer |

| Candy | Plow Mixer |

| Confection | Plow Mixer |

| Citric Acid | Plow Mixer |

| Soup Mix | Plow Mixer |

| Whey | Plow Mixer |

| Fruit | Plow Mixer |

| Icing | Plow Mixer |

| Glazes | Plow Mixer |

| Cereal | Plow Mixer |

| Flax Seed | Plow Mixer |

| Pectin | Plow Mixer |

| Vanilla Bean | Plow Mixer |

| Okara | Plow Mixer |

| Bouillon | Plow Mixer |

| Stevia | Plow Mixer |

| Tannin | Plow Mixer |

Partial application list. Please contact us to discuss your application in more detail.

Providing the product you need

B&P Littleford manufactures a wide variety of mixing and separating equipment ideal for food and beverage processing. This includes mixers, both batch and continuous as well as the TriVolution Compounder. B&P Littleford’s POD centrifuges are extensively used for liquid-liquid extraction and separation, while the pusher centrifuges efficiently and proficiently separate liquid-solid slurries.

BATCH MIXERS

Horizontal Plow Mixer

B&P Littleford Horizontal Plow Mixer creates fluid mixing action. The mixing tools project and hurl material away from the wall into free space in a crisscross direction, and inversely back again. The plow separates and lifts the product in a three-dimensional motion, while the number and arrangement of the tools insure agitation back and forth along the length of the vessel.

- Proteins

- Grated Cheese

- Cocoa

- Starch Reaction

- Bread Mix

- Cake Mix

- Spices

- Drink Mix

- Soft Drink Powder

- Gelatin Dessert

- Grain

- Wheat

- Soybean Meal

- Animal Feed

- Tea Powders

- Sugar

- Frosting

- Coffee Beans

- Oats

- Candy

- Confection

- Citric Acid

- Soup Mix

- Whey

- Fruit

- Icing

- Glazes

- Cereal

- Flax Seed

- Pectin

- Vanilla Bean

- Okara

- Bouillon

- Stevia

- Tannin

The size, number, geometric shape, arrangement, and peripheral speed of the mixing tools are designed to achieve this mixing action for each specific application. When required, the mix action is assisted by high shear chopper devices: independent high-speed motors with customized blades for adding shear to the product mix.

The Horizontal Plow Mixer also features:

- Large doors allow full interior access

- CIP/SIP hardware options available

- "Easy Clean" design available for batch or continuous material mixing

- Split seal assembly

- No special cleaning or maintenance tools required

- Bearings and drive components not disturbed during cleaning

Double Arm/Sigma Blade Mixer

Use B&P Littleford’s Double Arm/Sigma Blade technology to mix a wide variety of food products.

The Double Arm/Sigma Blade is simple to operate, easy to clean, and incudes a wide range of features that can be customized to meet your exacting carbon paste mixing specifications:

- Available in laboratory sizes and production sizes up to 900 gallons

- Sturdy stainless steel construction with required polish

- Spray injection

- E-Z clean shaft seals

- Direct shaft mount drives

- Variable speed motors

- Computerized controls

- ASME jackets for cooling and heating

- Cored agitators for enhanced product temperature control

- Tilt or valve discharge

- Full vacuum operation

- Vacuum equipped packing glands

CONTINUOUS MIXERS

Continuous Kneader

B&P Littleford Carbon Paste Continuous Kneaders (CK-CP Kneaders) are ideal for food and beverage processing.

- Delivers maximum throughput

- Provides consistent mixing

- Efficient mixing mechanism

- Easy access for maintenance

- East to maintenance costs

- Segmented system design means minimal tear-down required for maintenance or part replacement

- Peak shear rate lower than other compounders

- Operates at comparatively lower internal pressure

- Uniformity of temperature, pressure and narrow residence time distribution

- Greater surface area, more free volume and higher specific torque capability

- Total shear strain is controllable by adding or removing pins and flights

- Ability to measure melt temperature or inject liquids at any point along the process

- Efficient self-wiping mixing mechanism

B&P Littleford’s Continuous Kneaders are available in a wide range of screw sizes and include an array of features:

- Screw sizes from 30 mm to 300 mm with process lengths ranging from 8 to 20 L/D

- Compact high-performance gearbox, capable of screw speeds up to 750 rpm.

- Cored screw shaft option for fluid tempering.

- Electric heating and water cooling (standard) or fluid cooling (optional)

- Customized supporting equipment available include top feeders, side feeders, vacuum vent stuffers, vacuum connection chute, melt pump, discharge extruders and die face pelletizer

- Easy to clean split barrel results in faster product changeover

TriVolution®

With its unique and innovative design, B&P Littleford’s TriVolution® Compounder offers excellent dispersive and distributive mixing without damaging critical ingredients.

B&P Littleford’s TriVolution® Compounder reciprocates the process screw three times for every one revolution. Flights interact with pins in the barrel much in the same way a continuous kneader does. Its controlled shear with enhanced material exposure also works well for devolatilization and reactive processing.

The TriVolution Compounder features:

- Energy efficient

- Cost effective

- Uniquely design allows for faster mixing

SEPARATION EQUIPMENT

Podbielniak® Contactor (POD®)

B&P’s Podbielniak® Contactor (POD®) is a horizontal axis liquid-liquid centrifugal extractor that processes liquids for accelerated solvent extraction. The two main functions of this machine are liquid-liquid separation and the liquid-liquid extraction process through counter-current flow.

Use the POD for:

- Liquid smoke

- Citric Acid

- Citral extraction from Limonine

- Hops extraction

- Cooking oil

- Oleic Oils

- Lauric Oils

B&P’s Podbielniak® Contactor (POD®):

- Reliable: POD® has been in service for more than 60 years

- Runs smoothly: Uses a dual bearing lubrication system - one for normal operation, one for flush cleaning

- Durable: Lower operating rpm means rotating parts last longer

- Easy to clean: Rotor elements use Asco tubes and Ferralium alloy liners

- Sturdily construction: Made of 316 stainless steel. Non-contact parts and attachments in 304 stainless steel and chrome

Pusher Centrifuge

B&P Littleford's Pusher Centrifuges (liquid-solid separation centrifuges) relentlessly separate coarse solids from free-draining crystalline slurries in the most extreme conditions. The impressive reliability record for Pusher Centrifuges is grounded in its sound design, precise engineering and top-grade construction.

Pusher Centrifuges are developed and manufactured for standard products, but can be customized for special or difficult solid separation applications, including:

- Calcium Tartrate

- Citral extraction from limonine

- Hops

- Cooking oil water washing

- Refining Oleic oils

- Fish oils

B&P Littleford Pusher Centrifuges feature:

- Single-piece reversible wedge-slot screen that efficiently separates solids and liquids

- Screen supported by a centrifugally cast, milled-slot cage basket

- Heavy-duty bearings carry the main hollow shaft, which drives the basket

- Belt-driven hydraulic pump for energy efficiency, safety and reliability

- Internal, self-contained hydraulic piston driving the pusher shaft

- Rugged base provides rigid support for the entire rotating assembly

- Cooling coils that maintain the hydraulic system temperature at optimum levels

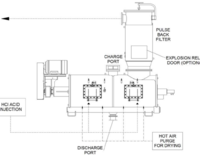

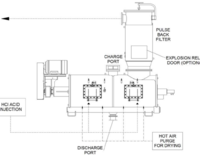

Innovative Dextrins Manufacturing

B&P Littleford’s technology brings efficiency and economy to manufacturing Dextrin, a carbohydrate with the same general formula as starch.

Manufacturing commercial Dextrin is usually a costly, time-consuming process that yields an inconsistent end product.

B&P Littleford has developed a superior system for manufacturing Dextrin in a single vessel.

Here’s how it works: Starch is charged into the processor unit. Starch is dried with hot air to ensure proper moisture levels. When moisture is removed and starch reaches a required temperature, HCl gas is injected onto the starch. After a predetermined reaction time and temperature, the product is ready for additional processing, cooling and discharging.

B&P Littleford’s Dextrin process provides:

- Better conversion efficiencies

- Controlled temperatures through heat transfer

- Improved production rates

- Efficient single unit processing during chemical reaction process

- Elimination of black specks in dextrin

- Capability of agglomerating the fine dextrin powder in the same unit

- Capability of blending in a flow agent

- Compliance to FDA, 3A, USDA standards

Delivering the service you deserve

B&P Littleford designs, develops and delivers a wide range of mixing, drying, compounding, reacting, extracting and centrifugal separation equipment for many different manufacturing applications.

- More than 100 years’ industry experience

- Quality parts and service

- Professional, knowledgeable staff

- Top-notch testing facilities

Ready to get started? Contact us today.

Dextrin Manufacturing

Learn more about how B&P Littleford's technology and machines can help improve your dextrin manufacturing processes. Request a quote today!

Dextrin Manufacturing

Learn more about how B&P Littleford's technology and machines can help improve your dextrin manufacturing processes. Request a quote today!